barcoding rfid systems RFID (Radio Frequency Identification Technology) and IoT sensor technology is helping companies eliminate the manual processes associated with locating and scanning barcodes, cutting costs and errors from manufacturing, distribution, transportation, and retailing operations. With RFID and IoT-based systems, our approach becomes even more critical. Sept 24, 2018 Using an NFC Reader as Keyboard Entry Device Over the past couple of years, we’ve helped customers achieve keystroke entry from an NFC tag. Barcode scanners have for years come with this as a standard feature yet .

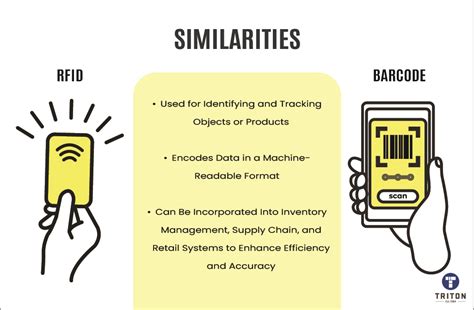

0 · similarities between rfid and barcode

1 · rfid technology pros and cons

2 · rfid tags pros and cons

3 · rfid pros and cons

4 · rfid chip pros and cons

5 · is rfid better than barcode

6 · differences between rfid and barcode

7 · barcode and rfid for warehouse

After a while I decided to reverse engineer the nfc reader so other people can still use amiibo on their original 3DS, 2DS and 3DS XL without buying the expensive nfc reader. I started by looking at existing documentation on the .

similarities between rfid and barcode

RFID systems are much more efficient for scanning a large number of items but can be more expensive and require more setup than barcodes. On the other hand, barcode systems can sometimes be more accurate but are less durable and secure than RFID. RFID is ideal for environments needing fast, automated data capture, while . RFID systems are much more efficient for scanning a large number of items but can be more expensive and require more setup than barcodes. On the other hand, barcode systems can sometimes be more accurate but are less durable and secure than RFID. RFID is ideal for environments needing fast, automated data capture, while barcodes are cost-effective and widely used. Both systems have unique pros and cons, making them ideal for different applications.

RFID (Radio Frequency Identification Technology) and IoT sensor technology is helping companies eliminate the manual processes associated with locating and scanning barcodes, cutting costs and errors from manufacturing, distribution, transportation, and retailing operations. With RFID and IoT-based systems, our approach becomes even more critical. Overall, RFID systems have many more features than simple barcoding systems, but both RFID and barcodes are good fits for certain applications. Each situation must be analyzed on its own in order to determine if RFID is the right call.

hsbc debit card contactless

Both barcoding and RFID offer unique advantages and cater to different operational needs and environments. While barcoding remains a cost-effective and widely adopted solution for many applications, RFID provides advanced capabilities for efficient and automated tracking in diverse industries. As RFID tags can store and share more information than barcode tags, an RFID-powered system allows you to leverage the data better. Better access to higher quality data allows you to use automation to optimize not only inventory management, but also your sales cycle.RFID technology helps companies track assets. Learn the 6 steps in developing & executing an RFID system, plus benefits: improved accuracy, speed & efficiency, and reduced operating costs. RFID and Barcoding are the two most effective and popular asset and inventory tracking technologies available. Both are very common in retail, transportation, manufacturing, and supply chain sectors, where asset tracking is critical.

Both RFID and barcodes are remarkable, time-saving tools for organizations wanting to improve the accuracy and efficiency of their asset tracking and data collection. Both have features unique to them, and use cases that leverage those advantages. Barcode and RFID (Radio-Frequency Identification) systems stand out for their distinct features. While both aim to streamline inventory management, they differ significantly in operation, capabilities, and suitability for various applications.

RFID systems are much more efficient for scanning a large number of items but can be more expensive and require more setup than barcodes. On the other hand, barcode systems can sometimes be more accurate but are less durable and secure than RFID. RFID is ideal for environments needing fast, automated data capture, while barcodes are cost-effective and widely used. Both systems have unique pros and cons, making them ideal for different applications.RFID (Radio Frequency Identification Technology) and IoT sensor technology is helping companies eliminate the manual processes associated with locating and scanning barcodes, cutting costs and errors from manufacturing, distribution, transportation, and retailing operations. With RFID and IoT-based systems, our approach becomes even more critical. Overall, RFID systems have many more features than simple barcoding systems, but both RFID and barcodes are good fits for certain applications. Each situation must be analyzed on its own in order to determine if RFID is the right call.

Both barcoding and RFID offer unique advantages and cater to different operational needs and environments. While barcoding remains a cost-effective and widely adopted solution for many applications, RFID provides advanced capabilities for efficient and automated tracking in diverse industries.

As RFID tags can store and share more information than barcode tags, an RFID-powered system allows you to leverage the data better. Better access to higher quality data allows you to use automation to optimize not only inventory management, but also your sales cycle.

RFID technology helps companies track assets. Learn the 6 steps in developing & executing an RFID system, plus benefits: improved accuracy, speed & efficiency, and reduced operating costs. RFID and Barcoding are the two most effective and popular asset and inventory tracking technologies available. Both are very common in retail, transportation, manufacturing, and supply chain sectors, where asset tracking is critical.Both RFID and barcodes are remarkable, time-saving tools for organizations wanting to improve the accuracy and efficiency of their asset tracking and data collection. Both have features unique to them, and use cases that leverage those advantages.

rfid technology pros and cons

rfid tags pros and cons

rfid pros and cons

If you want to use USB to connect to your reader / writer, I would go for the ACR122U. It works with libnfc out of the box like a charm: In case you decide for the smaller red module, you will .

barcoding rfid systems|barcode and rfid for warehouse