rfid manufacturing tracking Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory . In recent years, NFC technology has become a common feature in smartphones, enabling users to tap into the benefits of this . See more

0 · rfid tracking systems for inventory

1 · rfid tracking equipment and software

2 · rfid manufacturing inventory management

3 · rfid inventory tracking

4 · rfid based location tracking system

5 · rfid based asset tracking system

6 · rfid asset tracking software download

7 · asset tracking system using rfid

You can try NFC Tools or the MiFare Classic Tool to emulate cards from your phone, but in my .Smart Card Emulator. Use your phone as contact-less smart card. The Android Smart Card Emulator allows the emulation of a contact-less smart. card. The emulator uses Android's HCE to fetch process APDUs from a NFC .

RFID (Radio Frequency Identification) offers a robust solution that enables manufacturers to track assets automatically and efficiently without human interaction. How .

RFID Tracking System for Manufacturing. Improve manufacturing efficiency by getting real time information of your products. Add the ability to encode (or re-encode) items as needed. Know . Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory .

RFID (Radio Frequency Identification) offers a robust solution that enables manufacturers to track assets automatically and efficiently without human interaction. How RFID Enable Accurate Asset Tracking. RFID in manufacturing works by using radio waves to communicate between RFID tags and readers.

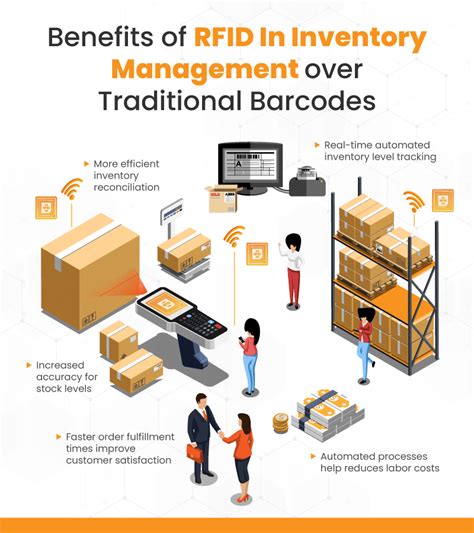

RFID Tracking System for Manufacturing. Improve manufacturing efficiency by getting real time information of your products. Add the ability to encode (or re-encode) items as needed. Know exactly where items are and their status with complete accuracy. REQUEST DEMO. Radio Frequency Identification (RFID) technology has gained significant attention in asset management. Let's explain the fundamentals of RFID technology, its components, and how they work together to provide location data. What is RFID? Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory management, enhanced asset tracking, and increased operational efficiency.

Track assets and manage inventories more efficiently in complex industrial environments with RFID labels that can fit any surface. Give every asset a unique digital identity your readers can radio in on, so you’ll know where your assets are, without needing line of sight. In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.In logistics, RFID optimizes goods movement, container tracking, and fleet management. It enables the monitoring of shipments in real time, thereby minimizing errors, enhancing route optimization, and ensuring timely deliveries.

RFID Tracking Solutions for IT, Manufacturing, Labs, Construction and Oil & Gas industries to track & monitor assets efficiently & accurately in real-time.RFID tracking transforms the way businesses monitor, manage, and optimize their manufacturing operations. By employing RFID tags and readers, manufacturers gain real-time visibility into inventory, production, and logistics, contributing to overall operational efficiency and cost-effectiveness in the manufacturing sector.RFID is a cost-effective way to track components or materials through the production process and ensure they are in the right place at the right time. It can also be used to track bulk containers, moulds or tools and ensure they are maintained properly. RFID (Radio Frequency Identification) offers a robust solution that enables manufacturers to track assets automatically and efficiently without human interaction. How RFID Enable Accurate Asset Tracking. RFID in manufacturing works by using radio waves to communicate between RFID tags and readers.

RFID Tracking System for Manufacturing. Improve manufacturing efficiency by getting real time information of your products. Add the ability to encode (or re-encode) items as needed. Know exactly where items are and their status with complete accuracy. REQUEST DEMO. Radio Frequency Identification (RFID) technology has gained significant attention in asset management. Let's explain the fundamentals of RFID technology, its components, and how they work together to provide location data. What is RFID?

rfid tracking systems for inventory

Radio Frequency Identification (RFID) technology has become an indispensable tool for modern manufacturing, offering a wide range of benefits, including improved inventory management, enhanced asset tracking, and increased operational efficiency.Track assets and manage inventories more efficiently in complex industrial environments with RFID labels that can fit any surface. Give every asset a unique digital identity your readers can radio in on, so you’ll know where your assets are, without needing line of sight. In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.In logistics, RFID optimizes goods movement, container tracking, and fleet management. It enables the monitoring of shipments in real time, thereby minimizing errors, enhancing route optimization, and ensuring timely deliveries.

does iphone 13 have nfc tag reader

RFID Tracking Solutions for IT, Manufacturing, Labs, Construction and Oil & Gas industries to track & monitor assets efficiently & accurately in real-time.RFID tracking transforms the way businesses monitor, manage, and optimize their manufacturing operations. By employing RFID tags and readers, manufacturers gain real-time visibility into inventory, production, and logistics, contributing to overall operational efficiency and cost-effectiveness in the manufacturing sector.

how to see what nfc reader checks for

rfid tracking equipment and software

rfid manufacturing inventory management

$20.89

rfid manufacturing tracking|rfid based location tracking system