rfid tag chipless Chipless RFID tags can be fabricated by simpler and cheaper processes than those used for conventional RFID tags. This fundamental difference is due to the absence of the silicon chip and therefore there is no need for a manufacturing process suitable for microelectronics.

Host-based card emulation. When an NFC card is emulated using host-based card emulation, the data is routed directly to the host CPU instead of being routed to a secure element. Figure 2 illustrates how host-based card .

0 · thermocouple chipless rfid

1 · inkjet printed chipless rfid tags

2 · ieee xplore chipless

3 · chipless rfid tags

4 · chipless rfid sensors

5 · chipless rfid review

6 · chipless rfid ireland

7 · chipless rfid aerospace

Please place only one Octopus card at a time during the enquiry / payment. Do not place two or more cards at the back of the mobile device simultaneously. The design of the NFC antenna and transmission power of each device varies. If .

In this paper, a review of the state-of-the-art chipless radiofrequency identification (RFID) technology is carried out. This recent technology may provide low cost tags as long as .

Chipless RFID tags are RFID tags that do not require a microchip in the transponder. RFIDs offer longer range and ability to be automated, unlike barcodes that require a human operator for interrogation. In this paper, a review of the state-of-the-art chipless radiofrequency identification (RFID) technology is carried out. This recent technology may provide low cost tags as long as these tags are not equipped with application specific integrated circuits (ASICs). This article throws light on RFID tag printing, data capturing techniques of chipless RFID, certain materials used for tag manufacturing, chipless RFID-based sensors, potential applications, followed by current challenges and future directions of chipless RFID tags. Chipless RFID tags are essentially paper-thin labels containing tiny metal particles that respond to electromagnetic signals. It doesn’t need a microchip to store information but linear encoding on resonating and reflective materials helps with data storage needs.

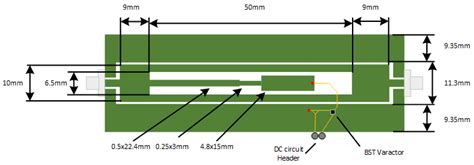

Chipless RFID tags can be fabricated by simpler and cheaper processes than those used for conventional RFID tags. This fundamental difference is due to the absence of the silicon chip and therefore there is no need for a manufacturing process suitable for microelectronics. In this study, prototypes of two distinct 8-bit chipless RFID tags operating in 3–6 GHz utilising L-resonators discussed in Section 2 are reported. The chipless tags have been designed using CST Microwave Design Studio and printed on the Roger RT 5880 substrate.

Discover how chipless RFID technology offers a powerful, cost-effective alternative to traditional RFID for tracking inventory, assets, and products. Explore its benefits, applications, and future potential in industries like retail, supply chain, and beyond. A comprehensive review of reported time-domain chipless RFID tags has been discussed with a focus on size, data capacity, and reading range.

What is a chipless RFID tag? “Chipless RFID” is a generic term for systems that use RF energy to communicate data but don’t store a serial number in a silicon microchip in the transponder. Some chipless tags use plastic or conductive polymers instead of silicon-based microchips.

What is a Chipless RFID Tag? Chipless tags are RFID tags without an integrated microchip. Chipless tags work by incorporating materials in the tag that reflect back a portion of the radio waves beamed at them from the reader.Chipless RFID tags are RFID tags that do not require a microchip in the transponder. RFIDs offer longer range and ability to be automated, unlike barcodes that require a human operator for interrogation. In this paper, a review of the state-of-the-art chipless radiofrequency identification (RFID) technology is carried out. This recent technology may provide low cost tags as long as these tags are not equipped with application specific integrated circuits (ASICs).

This article throws light on RFID tag printing, data capturing techniques of chipless RFID, certain materials used for tag manufacturing, chipless RFID-based sensors, potential applications, followed by current challenges and future directions of chipless RFID tags. Chipless RFID tags are essentially paper-thin labels containing tiny metal particles that respond to electromagnetic signals. It doesn’t need a microchip to store information but linear encoding on resonating and reflective materials helps with data storage needs. Chipless RFID tags can be fabricated by simpler and cheaper processes than those used for conventional RFID tags. This fundamental difference is due to the absence of the silicon chip and therefore there is no need for a manufacturing process suitable for microelectronics. In this study, prototypes of two distinct 8-bit chipless RFID tags operating in 3–6 GHz utilising L-resonators discussed in Section 2 are reported. The chipless tags have been designed using CST Microwave Design Studio and printed on the Roger RT 5880 substrate.

Discover how chipless RFID technology offers a powerful, cost-effective alternative to traditional RFID for tracking inventory, assets, and products. Explore its benefits, applications, and future potential in industries like retail, supply chain, and beyond. A comprehensive review of reported time-domain chipless RFID tags has been discussed with a focus on size, data capacity, and reading range.What is a chipless RFID tag? “Chipless RFID” is a generic term for systems that use RF energy to communicate data but don’t store a serial number in a silicon microchip in the transponder. Some chipless tags use plastic or conductive polymers instead of silicon-based microchips.

thermocouple chipless rfid

what are the benefits of getting the rfid chip

Explore a wide range of our Nfc Cards Blank selection. Find top brands, exclusive offers, and unbeatable prices on eBay. Shop now for fast shipping and easy returns!

rfid tag chipless|chipless rfid tags